Tariffs aren’t just about cost—they’re reshaping global supply chains and redefining corporate risk in ways many teams didn’t anticipate.

As tariff volatility continues to dominate headlines and influence boardroom strategy, it is all too common for companies to deploy every cost-saving lever including supplier changes, origin reclassification, and alternative routing, to offset rising duties. These moves help soften the impact, but they also open the door to something far more dangerous: new export control and denied party screening risks hiding in those tariff mitigation strategies.

New suppliers may be linked to restricted entities. Newly selected intermediaries may trigger Office of Foreign Assets Control (OFAC) exposure. Alternative shipping routes may involve embargoed or high-risk jurisdictions. And relabeling or reclassification initiatives can inadvertently cross into export license territory. And in the rush to avoid tariff costs, these compliance implications are often missed entirely.

In a year where tariffs have become the defining theme of supply chain strategy, the risk landscape is shifting just as fast. To stay compliant—and competitive—organizations need smarter denied party screening and stronger export license controls that adapt to the

Key Takeaways

- Tariff mitigation is now a strategic reflex—but the speed of change often outpaces compliance review creating hidden export control risks.

- Supplier switches and transshipment routes can trigger enforcement implications. New vendors, unfamiliar trade hubs, and alternative routing decisions can add ownership, jurisdiction, or licensing risks that wouldn’t appear under stable sourcing models.

- Automated denied party screening and export license tools close the risk gap. Technology that enables thorough supplier due diligence and accurate licensing prevents tariff-driven strategies from turning into violations.

- Cross-functional alignment is critical: Legal, finance, and logistics teams must collaborate to integrate compliance into tariff mitigation strategies.

- Tariffs aren’t going away—prepare for volatility: Geopolitical uncertainty and trade policy shifts will continue into 2026, making compliance automation essential for resilience.

The Tariff Volatility Era: What’s Driving Rapid Supply Chain Changes

The current tariff environment is defined by constant movement. Ongoing U.S.–China tensions and retaliatory tariff cycles continue to reshape cost structures with little warning, forcing businesses to react quickly just to protect margins. Now, with the Supreme Court reviewing presidential tariff authority, another layer of uncertainty looms. Depending on the outcome, billions in duties could be upheld or rolled back—yet even a ruling won’t eliminate tariffs from the equation. For executives, this signals a future of continued unpredictability.

Descartes’ survey of 800 compliance and supply chain leaders reinforces this reality: 50% cite tariffs as their primary trade compliance challenge, and 65% say compliance is becoming more difficult, driven by operational disruption and instability in trade governance. Tariff lists are not only expanding and contracting—they’re being reinterpreted, reviewed, and reissued in ways that leave companies unsure whether today’s duty rate will hold next quarter.

Image 1. Descartes Survey Insight: Tariffs Dominate Trade Compliance Concerns

In response, more organizations are leaning on tariff engineering, reclassification strategies, and alternative production hubs to minimize the financial pressure. For leaders evaluating these tariff-specific tactics, our Tariff Volatility Survival Guide provides helpful context—but the compliance risks tied to these strategies require equal attention.

These moves put legal teams under pressure to validate new interpretations, finance teams recalculating landed costs frequently (sometimes weekly), and logistics teams reconfiguring trade lanes in real time as sourcing regions shift. The urgency to reduce landed costs is real, but when changes move faster than compliance review, sanctions exposure, denied party violations, and export control missteps can escalate quickly.

Where Tariff Mitigation and Export Compliance Collide

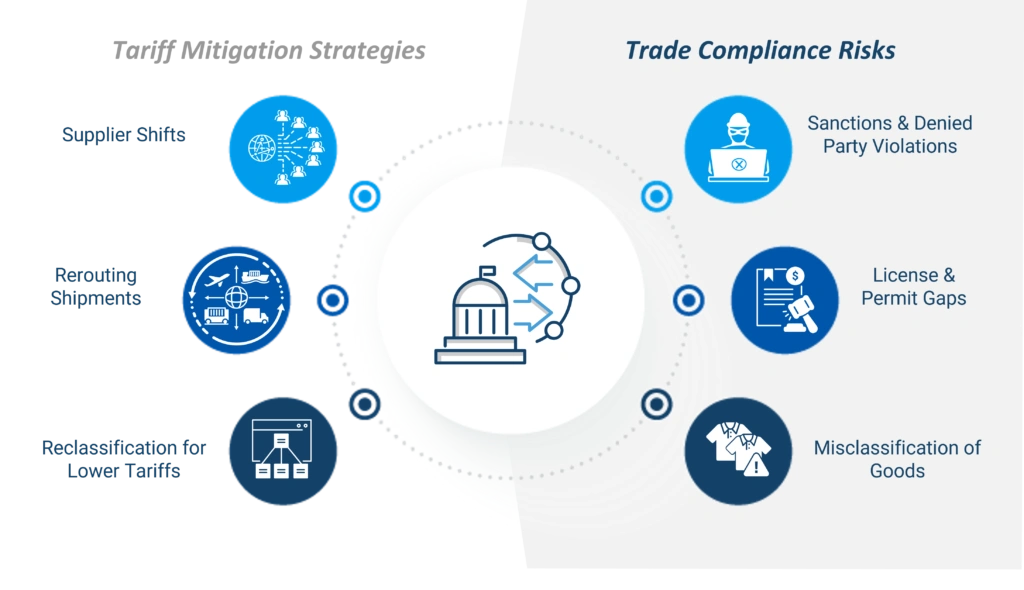

Tariff workarounds designed to reduce duty exposure are now routine. But here’s the question every compliance leader should ask: How could these tariff mitigation strategies be putting our company at export compliance risk? What looks like a smart tariff move can quickly turn into a sanctions violation, import / export licensing failure, or denied party screening oversight if compliance isn’t baked into the decision. Below is where the collision happens most often.

Image 2: Tariff Mitigation Decisions and Trade Compliance Exposure

Supplier Shifts: New Partners = New Risks

The race to onboard lower-tariff suppliers often moves faster than due diligence can keep up. Companies may prioritize duty reduction while inadvertently skipping deeper ownership screening, end-use checks, or export-control assessments. This is especially risky when switching into regions with opaque corporate structures or high Entity List activity. Hidden beneficial ownership ties can pull a “clean” supplier into OFAC, Bureau of Industry and Security (BIS), or EU restriction territory—sometimes months after contracts are signed.

Example of lapsed supplier due diligence: A global freight forwarder failed to implement OFAC screening solutions and compliance processes resulting in prohibited transactions with suppliers who were on the Specially Designated Nationals (SDN) and Blocked Persons list.

Transshipment and Country of Origin (CoO) Changes: Not Worth the Risk

Adjusting routes or altering Country of Origin (CoO) to reduce tariff impact may seem like a quick fix—but it’s a high-risk strategy that can backfire. These tactics often introduce unexpected export licensing obligations, sanctions exposure, and customs violations. Even temporary stops in certain jurisdictions can turn a routine shipment into a controlled transaction, attracting attention from regulators such as BIS, OFAC, and DOJ.

Example: A company reroutes shipments through the United Arab Emirates (UAE) or Mexico to avoid Section 301 duties—without realizing that new end-user checks or regional controls now apply under Export Administration Regulations (EAR) or OFAC rules.

Tariff Engineering and Reclassification = Regulatory Complexity

Tariff engineering can unintentionally trigger export control complexity. A change in product composition, software configuration, or technical specification may move an item into a different Export Control Classification Number (ECCN)—sometimes into a more restricted category. Meanwhile, reclassification to reduce duties can conflict with export licensing obligations if teams fail to reassess accompanying export control status. Companies that treat classification as a one-time task risk non-compliance. A repeatable, software-driven classification process with regulatory decision trees prevents misunderstandings and ensures traceable, audit-ready rationale.

Example: A device modified to qualify for a lower Harmonized Tariff Schedule (HTS) rate ends up containing components that elevate it into a controlled technology category—requiring licensing the company didn’t plan for.

Inadequate Documentation and Audit Trails

In the rush to execute tariff-mitigation strategies, documentation is often an afterthought—and that’s where companies increase their enforcement exposure. Missing or inconsistent records around country of origin, substantial transformation, supplier vetting, or routing decisions undermine the organization’s defense posture. This is especially damaging when submitting a Voluntary Self-Disclosure (VSD), where regulators evaluate not just the issue but the strength of the audit trail. Weak documentation makes it harder to prove intent, validate classification decisions, or defend complex supply chain movements.

Example: A company reroutes production from China to Vietnam to avoid tariffs but can’t produce documentation proving true origin or transformation. During an audit, regulators dispute the CoO—and the company is hit with duty penalties and questions about export control compliance.

How Smart Denied Party Screening and Automated Export License Controls Close the Gap

Tariff mitigation without compliance is a gamble. Switching suppliers or rerouting shipments can expose you to export control risks if not monitored continuously. Static checks can’t keep pace with this level of operational fluidity. What’s needed is a dynamic system that screens every new relationship, monitors risk as trade lanes shift, and automates license management.

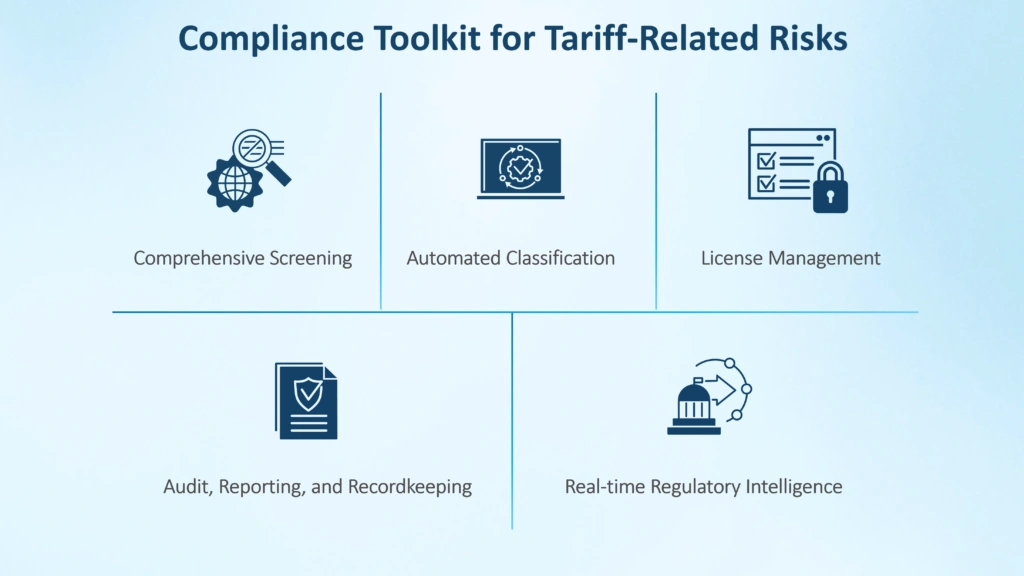

Robust global trade compliance software makes this possible—turning tariff mitigation from a gamble into a smart, compliant strategy that protects margins and reputation. Below is how best-in-class tools help compliance teams walk that line with confidence.

Image 3. 5 Export Compliance Tools Every Risk-Aware Team Needs

Dynamic Denied Party Screening for Supplier Due Diligence

When sourcing teams pivot to lower-tariff suppliers or alternative trade lanes, the risk profile changes instantly. Dynamic denied party screening software performs comprehensive supplier due diligence and helps ensure no shift exposes the company to restricted entities or hidden counterparties.

- Embedded screening in ERP/TMS workflows prevents shipments or purchase orders from bypassing compliance checkpoints.

- Sanctioned party ownership screening catches shifts in beneficial ownership so a supplier doesn’t quietly become a restricted entity.

- Automated rescreening triggers when trade routes, brokers, or suppliers change—ensuring a new logistics decision doesn’t introduce surprise exposure.

Export Classification Intelligence

Tariff engineering, design modifications, or CoO changes often affect not only HTS codes but export control classifications. Automated export classification tools with guided workflows help teams consistently reassess ECCNs, dual-use implications, and de minimis or re-export rules whenever product specs or origins shift. Built-in logic for BIS, OFAC, EU, and other jurisdictions ensures that tariff-driven product decisions don’t inadvertently push an item into a category requiring export licensing or enhanced controls.

Automated Export License Management

As supply chains reroute to avoid tariffs, export licensing obligations can shift faster than teams can manually track. Trade compliance software evaluates lanes and end uses against jurisdictional rules, then opens, tracks, and renews export licenses before a shipment gets stuck.

- Real-time checks tied to new routing or supplier decisions determine when an export suddenly requires a license.

- Instant alerts notify teams when a new sourcing strategy triggers the need to apply a license for technical data or goods.

- Centralized value and quantity tracking maintains accurate export license limits and prevents accidental over-usage as supply lines shift across global sites.

- Systematizes export license management including tracking, expiration alerts, and renewals.

Trade-Lane–Aware Risk Monitoring

Many tariff-mitigation strategies push goods through higher-risk regions or nontraditional lanes. Trade-lane–aware monitoring continuously evaluates jurisdictions associated with transshipment, tariff circumvention, or diversion concerns. Automated alerts flag abnormal patterns—such as sudden shifts into UAE, Mexico, or Southeast Asian hubs—giving compliance teams early warning before a cost-saving routing strategy crosses into regulatory gray areas.

Full Audit Trail for Tariff-Driven Strategy Shifts

Rapid operational changes require equally strong documentation. A centralized audit trail captures every supplier switch, routing adjustment, and compliance checkpoint tied to tariff-driven strategy shifts. This visibility is essential during regulator inquiries into end-use, end-user, or transshipment decisions.

- Automated records show regulators that changes—supplier switches, new trade lanes, or transshipments—were still controlled and reviewed.

- Traceable changes tied to tariff-driven strategy shifts provide transparency for both internal and external audits.

- Configurable approval workflows ensure compliance review happens before onboarding a supplier or shipping a product.

Risk-Proof Your Tariff Mitigation Strategies and Protect Margins with Descartes

As tariff pressures continue to reshape sourcing, production, and routing decisions, the organizations that thrive will be the ones that modernize their compliance infrastructure in parallel. Cost-saving strategies only work when they’re backed by controls that adapt just as quickly.

Descartes global trade compliance platform gives every team the guardrails they need to move with confidence. Our robust denied party screening, export operations automation, classification tools, and risk management don’t just support compliance—they empower Sourcing and Procurement to vet new vendors quickly, Logistics and Trade to enable compliant shipping and customs clearance, and Legal/Governance teams to meet regulatory and reputational standards.

See how Descartes helps leaders protect revenue and stay ahead of regulatory change. Request a demo.

Find out what our customers are saying about Descartes Denied Party Screening on G2 – an online third-party business software review platform. Additionally, you can read this essential buyer’s guide to denied party screening to help you select a solution that fits your needs.